What Is Wire Forming? How It Works, Where to Get It, & More!

Wire Forming

Wire forming is a precision technique used to mold straightened wire into distinct and captivating shapes and designs.

Below are some highlights of the process:

- Wire forming is crucial in all types of manufacturing activities, like automobile production, food production, shipping and handling, medical equipment manufacturing, and a whole lot more.

- The wire forming process is not limited to a single metal. It can incorporate a diverse range of metals, including steel, stainless steel, aluminum, copper, brass, and various alloyed metals.

- A range of equipment is available for wire forming, from manual crafting techniques to advanced CNC programmable machines.

In this article, we’ll dive deeper into the wire forming process and techniques, types of wire forming, and how we can help at Vogan Manufacturing, your go-to wire forming shop.

We have the expertise, equipment, and interest to complete your order effectively and efficiently, giving you a wonderful finished product and overall experience.

If you have any questions about a prospective project or an existing order, don’t hesitate to reach out!

What Is Wire Forming?

Wire forming is a technique for changing a straightened wire into different lengths and sizes tailored for various industries. Before any shapes are formed, the initial wire is coiled and then straightened.

Since wire forms are very pliable, they’re easily transformed into a range of specific shapes and designs, and lend themselves to an array of projects. This explains why wire forming has existed for so long, dating back to The Bronze Age.

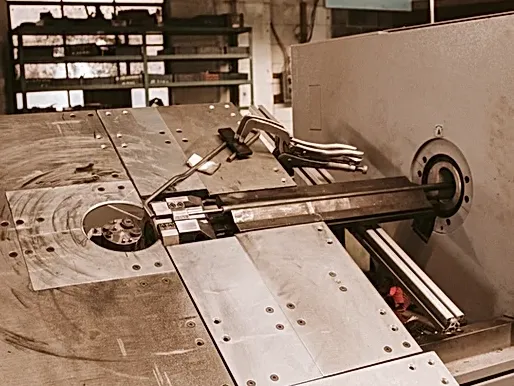

Many different equipment types are used for wire forming, including conventional equipment that requires manual labor, semi-autonomous equipment, and fully automated devices.

How Are Wire Forms Made?

Wire forms are made using processes like bending, extrusion, upsetting, and twisting. Wire form manufacturers also use techniques like CNC wire bending, manual wire forming, and fourslide stamping.

There’s no shortage of processes and techniques when it comes to wire forming, and we at Vogan Manufacturing Inc. employ many of these when creating your custom project.

Wire Forming Processes

Bending—the introduction of an angle to a straightened wire—is the most common process in wire forming, allowing for the creation of three-dimensional shapes. However, in addition to bending there are numerous other wire forming processes, including:

- Extrusion: The wire is carefully manipulated by exerting pressure as it is passed through a smaller opening than its own diameter.

- Upsetting: The wire is widened and shaped through axial direction compression

- Twisting: The act of twisting wires allows for the combination of various lengths, the formation of precise shapes, and the utilization of spring-back forces.

- Stamping: The wire is threaded through a stamping press that utilizes specialized forming tools known as dies to manipulate and mold the part.

These are just a sampling of the processes manufacturers use. Some others include welding, chamfering, and weaving.

Wire Forming Techniques

Wire forming machines, whether manual or automatic, have seen significant advancements. Automation, in particular, has revolutionized the industry, allowing for increased efficiency and creating more complex wire form parts.

- Manual Wire Forming: As the name suggests, manual wire forming is done by a person by hand, without any tools. Usually, hand levers and spindles are used for this method.

- Coil Wire Forming: Coil, also known as spring wire forming, is the process of wrapping wire around a metal blank.

- Roll Wire Forming: Roll forming is a highly efficient technique for manufacturing wire parts in various shapes, including flat and round forms.

- Pneumatic Wire Forming: Wire is efficiently guided into the straightening machine, which is shaped to the desired form and then pneumatically cut to the correct length.

These are just some of the techniques used for wire forming, which are similar to wire forming processes. Others include

CNC wire bending and hydraulic wire forming.

Examples of Wire Forming

So, what is an example of wire forming? The possibilities for wire shapes, configurations, and forms are infinite as new ones are consistently being created. Wire forming allows for producing any conceivable shape, from complex three-dimensional designs to basic hooks and springs. A wide range of products utilize wire forming in some capacity.

Below are some examples:

- J Hook: These hooks offer both material protection and hangability. With their notched design, they can easily be hung in place. Plus, the Double J hooks have an impressive load-bearing capacity when attached to a strap.

- S Hook: The S hook is designed with both ends bent to create its distinctive S shape. This versatile hook is commonly used for hanging storage and organizing cables and cords to ensure safety.

- Springs: Springs are the most prevalent and widely employed type of wire form. They are essentially coils that have been tightly wound into a spiral shape to meet specific tension needs. The selection of a particular type of spring is based on its intended use and application.

- Linchpins: Vital components, linchpins are placed at the end of an axle to ensure the wheels remain securely in place. They’re fabricated using different materials, such as aluminum, zinc, brass, and stainless steel.

Other types of wire forms are utility hooks,

powder coating hooks,

d rings, and wire guards.

What Are Wire Forms Used For?

What are wire forms used for? A whole lot! For instance, here at Vogan Manufacturing Inc., we service many industries, such as:

- Construction: Brackets and clips

- Medical: IV hooks; coat hangers

- Industrial: Handles

- Agriculture: Dairy equipment

- Display: Ornamental designs

Additionally, we are able and eager to help with any projects you have on the horizon by creating custom parts for you. No matter what project you have in mind, we can create the ideal part to meet your needs!

Materials Used in Wire Forming

A slew of metals are used in wire forming, most commonly stainless steel and steel. Some more examples include:

- Galvanized Wire

- Brass Wire

- Copper Wire

- Aluminum Wire

- Bright Basic Wire

As you can see, there are a host of potential materials to choose from when wire forming. The choice of material depends on the specific requirements of the wire forming project. Different materials offer different properties and characteristics, allowing for versatility in various applications.

The Finest in Wire Forms Since 1979

Now you know more about wire forming and more about us at Vogan Manufacturing Inc. We have knowledgeable and friendly staff to assist with your wire forming needs—no matter the scale of the project. Whether you have a small request or a large one, we’ll handle it with top-notch attention to detail and professionalism.

We also have years of combined experience as well as the premium equipment necessary to make your vision a reality. Please let us know if you have any questions or would like to place an order.