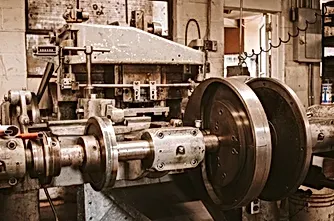

Prototype Wire Forming

We offer custom prototype wire forms to help you explore and scale the products you need to grow your business.

Prototype wire forming is a way to produce complex and custom designs using a variety of metals to explore and scale the products you need to grow your business. Wire forming keeps costs low, and we don't need tools apart from the wire forming machine.

Get The Prototypes You Need To Move Business Forward

Producing high-quality wire forms for your products is crucial to their success. It’s a fast and affordable way to develop and refine your designs. Whether you're in the early or advanced stages, we can help.

Broad Prototyping Capabilities

We offer two main types of wire forming. What you're creating will determine which type is best for you. We can help advise you on this and pick the ones most suitable to your needs.

CNC wire forming and bending

CNC wire forming is the more technical of the two wire forming options. We use it when prototypes need to meet the highest standards and tolerances, such as in the medical or automotive industry. It allows you to create products that fit perfectly and will be reliable.

CNC machines are entirely computer-controlled, guaranteeing speed and accuracy. They can create complex parts in both 2D and 3D designs. CNC machines can handle wire thicknesses from 0.5 mm to 12 mm (.020" to .472").

Fourslide wire forming

Fourslide Wire Framing is for products that require complicated wire forms, such as industrial machinery, consumer products, and the products in the electronics industry.

It provides the flexibility to create intricate wire forms with multiple shapes and bends, which is excellent for complex custom prototypes.

Flourslide is a better options for when producing parts at volume (usually over 20,000 pieces) as they are faster to produce than CNC, which results in a lower cost per piece.

To read more about the benefits of prototyping,

check out this article.

Why go with Vogan?

You won’t have to worry about prototypes that don’t meet your high standards. Before we proceed, we down with you, listen to your needs, and ensure you get exactly what you want.

Big Enough To Deliver Anything You Need

We can take on any wire-forming project you have in mind. We help companies of all sizes and have the resources to handle anything you can throw at us.

Lean Enough To Prioritize Quality and Craftsmanship

We treat every prototype wire-forming job we take on for our clients with care and attention to detail. We know how important your job is, and our highly dedicated team takes pride in what they do and wants to see you succeed.

What Can We Prototype For You?

If you are ready to bring your project to life, we're here to help you get started with prototype wire forming. Allowing us to develop your prototype will help you see that you're one step closer to releasing your dream product.

Industries We Can Prototype For

We can help with prototypes no matter what industry you're in, but here are some of the most common ones we work with:

- Automotive - Used for engine parts and interiors

- Medical - These products must meet strict guidelines, and prototyping can help with that.

- Consumer Products - Most products you see in your house have gone through some form of prototyping.

- Industrial - We can help prototype clamps, springs, pipes, and hooks.

What Types Of Metals Can We Use?

We have the materials you need for your prototypes, from common metals like steel, stainless steel, and aluminum to specialized alloys. We can also help advise you on what metal will work best for your product.

Let’s Start Your Prototype Wire Forming Project Today

Take the first steps to bring your project to life.

Contact us for high-quality, custom wire prototypes, and let’s turn your ideas into reality.